Hitting the Heights with Vertigo

The Kiwi superyacht scoops design awards.

Text: Derek Powell

Recipe for Extreme Audiovisual: First, take the world’s most beautiful sailing yacht and pour in a mansion-sized fibre optic digital video and audio entertainment system. Next, whisk in several mission-critical navigation systems and pipe everything into the smallest container possible. Shake and swirl the resulting cocktail constantly in salt water while sending it to the other side of the world. When done, serve to a discriminating audience accustomed to only the best of everything. Oh, and did I mention there are to be no hitches, glitches or faults… ever?

I’m sure most of us would blanch at the thought of quoting on such a daunting set of expectations but for New Zealand integrator Liquid Automation, this is fast becoming its bread and butter [enough with the culinary references! – Ed].

Liquid Automation has won awards previously for work in marine categories but this time the company has walked away with the prestigious 2012 AVIA for Best Government or Commercial Installation over $500,000 – giving well deserved recognition at a completely new level. The project was the super yacht Vertigo built by New Zealand’s Alloy Yachts International.

We’ll get to the details of the audiovisual gear in a moment, but so you can gain some perspective on the job, here are some facts and figures about the boat. At 67m long and with a beam of 12.3m, Vertigo is comfortably larger than say, Cook’s barque Endeavour which was less than half that length at 32m and only 8.2m across the beam. She is a fully-capable ketch-rigged sailing craft, but also sports a pair of 1400hp Caterpillar C32 diesel engines, giving her a cruising speed of around 12 knots. The interior, designed by Christian Liaigre, is fitted out for 12 passengers in the kind of walnut and lacquer luxury you’d expect to find in the best seven-star hostelries of Paris or Monaco. Vertigo herself won Sailing Yacht of the Year along with a string of design awards.

Naturally, audiovisual is ubiquitous in the craft with a full theatre system, individual cabin video and audio systems, and a nightclub style party sound system. But the digital fibre backbone also encompasses all of the boat’s advanced navigation systems including the sophisticated integrated bridge system, which is similar to the glass cockpit found in the latest generation of commercial airliners. So to get a true handle on the project, I spoke with Sam Ashton, Liquid Automation’s system designer and project manager, and also with his client Eamon O’Connell, electronics design manager for Alloy Yachts.

BEST IN SHOW

Following its AVIA award win, Liquid Automation won further recognition on the world stage with the 2012 Global CEDIA gold medal for Best Technical Design for a Special Project. Additional awards for Vertigo include:

2012 winner International Superyacht Society Award: Best Sailing Yacht over 40m

Monaco Yacht Show: Prix du Design Award

2012 winner World Superyacht Awards: Sailing Yacht of the Year; Best Sailing Yacht 40m and over

2012 winner – ShowBoats Design Awards for Exterior Design and Styling; Interior Layout; Recreational Space Designed for Guest Use

FIGHT FOR SPACE

Both men were unanimous when I asked them to nominate the greatest challenge for super yacht integrators. “Space!” declared Sam. He explained that for famous interior designers, AV equipment was well down the priority list. “We really do get whatever space is left and we fight tooth and nail to get what we can.” Sam admitted to learning a few tricks over the years for creative positioning of racks. “…And with that comes heat,” he continued, noting that air handlers and over-temperature alarms were a must to allow equipment to operate in cramped quarters. From the boat builder’s perspective, Eamon backed him up. “Space is number one,” he said, adding that because an audiovisual installation was in virtually every compartment, it was crucial for the boat builders to get accurate equipment housing and cabling requirements from the audiovisual designers early in the planning process.

“The next biggest challenge is figuring out what the customer actually wants,” Eamon said, noting that sometimes owners weren’t sure what they wanted. “But this particular client was well aware of what he wanted the system to do,” he continued. “The quality of the audio was probably more important to him than the quality of the video, so we had to work quite hard to deliver an audio experience in keeping with the rest of the boat.”

With this in mind, Sam and the Liquid Automation team made sure they lavished special care on every detail of sound quality. The owner’s stateroom features a large screen TV that rises from the floor and swivels so it can be viewed either from the bed or from the couch. To keep the correct stereo image, the DSP system changes to match the rotation of the screen so as the screen pivots, the channels flip between speakers, maintaining the left and right perspective relative to the picture.

“”

the Alloy Yachts team built a full mock-up of the bridge from plywood so that Liquid Automation could test the distribution and control system thoroughly

SPECIAL FEATURES

Liquid Automation customised Google Earth interface: A 3D model of the yacht follows the position of the vessel in real-time. Using a touch panel, the user can virtually fly from the yacht to the surrounding area.

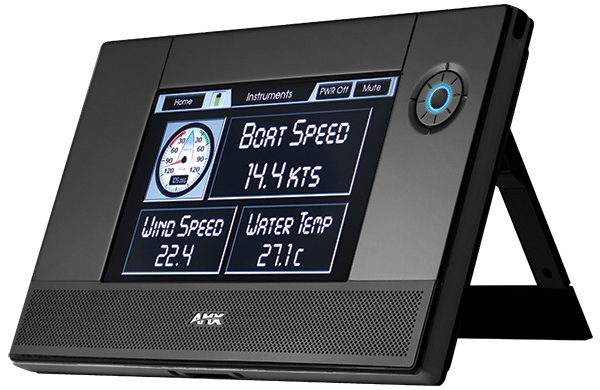

Navigation instrumentation is relayed on the touch panels so the guest can see current yacht information such as boat speed, wind speed, wind direction, water temperature.

ROCK THE BOAT

Meanwhile, the cockpit and after-deck needed to become party central when Vertigo makes port in Ibiza, so its audio system was carefully engineered to take on a variety of roles. Even before the boat was built, EASE plots were done from the 3D drawings of the space. The Liquid Automation team took special care to load the model with the acoustic properties of all the proposed fittings and furnishings, right down to the curtains, to determine optimum speaker locations. To supplement coverage on the open rear deck, JBL powered speakers are stowed in watertight compartments ready to be deployed onto spigots built into the deck.

“At commissioning, we did time alignments and tweaked the frequency response of the room,” Sam said. “Then we added a dynamic EQ so that when the system’s at a low volume, it’s a nice warm, even sound. But as they really crank it up, at a certain SPL it will change to more of a nightclub sound… On the water, it just sounds fantastic.”

However, don’t imagine for a moment that video has been forgotten. This is where the Crestron Digital Media system comes into its own. The fibre backbone, chosen for its immunity to noise and interference, serves not just the 25 entertainment monitors and the Projectiondesign F12 video projector but also distributes the navigation systems to the bridge, which was a whole new challenge.

On the bridge, sources ranging from GPS to depth sounders, radar, and even a night vision camera mounted high on the mast need to be routed to six widescreen displays running at 1920×1200. The sources, mostly DVI but at varying resolutions, were scaled and then fed into a 16×16 matrix before being linked by fibre to the bridge.

But that’s not all. Using the USB breakaway feature of the Crestron DM system, the controls for each system accompanied the video. So if a GPS display, say, was routed to Monitor One, then a trackball on the dashboard could be associated with that monitor and assigned via the Crestron USB breakaway function to provide control of menu features to operate the GPS base station. Then if the input was changed to display radar, the USB routing would change to give the trackball control of the new system.

The Crestron also allowed RS232 control of each monitor so that at night, all six could be uniformly dimmed to allow the crew to retain their night vision through the windscreen while still monitoring the instruments.

With such vital systems, nothing was left to chance and Eamon described how the Alloy Yachts team built a full mock-up of the bridge from plywood so that Liquid Automation could test the distribution and control system thoroughly, months before the boat was ready to be fitted out.

GEAR LIST

CONTROL

11 x AMX processors

9 x Crestron processors

9 x Crestron touch panels

11 x AMX touch panels

Crestron PLC interface allows AV/Nav selection and CCTV control from Alloy Yachts’ custom bridge stations.

AUDIOVISUAL SERVERS

18 x Apple TVs

2 x Mac Pro 12-core servers.

VIDEO

25 screens (excluding navigation screens) consisting of the following:

Projectiondesign F12 1080p projector

26-inch Aquavision flush-mount TVs

55-, 46-, 40-, 32-, 22-inch Samsung TVs

10.2-inch Clarion flip-down screens with built-in DVD player (for all crew cabin bunks)

LIGHTING

Lutron control system

AUDIO

BSS SoundWeb distribution.

Saloon Theatre: Crestron Procise surround sound processor with Lexicon and Crown CTS amps, JBL Synthesis speakers and 2 x 15-inch JBL subwoofers in custom designed enclosures.

Cockpit Theatre/Aft deck: 6 x JBL in-ceiling satellite speakers, 15-inch JBL subwoofer in custom designed enclosure and removable powered aft deck party speakers with custom DJ inputs.

Owner’s Suite: Crestron Procise surround sound processor with Lexicon and Crown CTS amps, 7 x JBL in-ceiling satellite speakers and a 15-inch JBL subwoofer in a custom designed enclosure.

Owner’s Ensuite Port: 2 x Proficient 8-inch in-ceiling speakers.

Owner’s Ensuite Starboard: 2 x Proficient 8-inch ceiling speakers.

Other Zones: SpeakerCraft speakers with Crestron amps

HYBRID CONTROL

All through the three-year project, testing and mock-up systems were a vital component in achieving a reliable outcome. Unusually, the control system is a hybrid with AMX touchscreens managing the Crestron back-end. The owner had seen AMX touchpanels in other yachts and made this part of his specification but at the time, there was no AMX switching and fibre transmission comparable to Digital Media. During several months of testing, Liquid Automation tried a number of approaches to system programming before settling on their current programming solution. “Since the launch we haven’t had one issue with AMX controlling Crestron. It’s been extremely reliable so we’re very happy with that – and the owner loves it,” Sam said.

RELIABILITY IS EVERYTHING

Although there are countless ways this project embodies excellence, Eamon spelt out his number one priority for electronics: “Reliability is the only thing that we care about really. We’re aware that we have to do tricky things but if we make a system that’s capable of a lot and it only works 95 per cent of the time, then we’ve failed utterly. Every time a guest goes to use it, it must do exactly what they expect it to do.”

By that criterion (as well as many others) Liquid Automation can stand tall as there has yet to be any downtime attributed to the audiovisual and control system. Keeping things that way despite the constant pitching and rolling of the boat requires constant checking which, thanks to the novel Ihiji IP monitoring system, the team can achieve even half a world away. The Ihiji status screen at Liquid’s Auckland office constantly monitors every device on the Vertigo network and can drill down to check the status of connected devices on Cresnet or RS-232, flagging any device that reports a problem.

“One day when we arrived at the office, we noticed that a whole bunch of audio devices had dropped offline,” Sam recalled. Realising that all the affected devices were connected to the same power board, they quickly emailed the boat’s engineer. Half a world away it was late at night, so in the morning the engineer read his mail, checked the power board and re-attached an IEC lead that had fallen out. “He was able to get it all back up and running before the owner, who was on board with his family, woke up and went to use the system.”

Judging from its awards so far, Liquid Automation has the right recipe for reliability, innovation and excellence. Together with Alloy Yachts International, it seems certain the team will continue to make waves on a world stage.

PROJECT PERSONNEL

Sam Ashton – System design and project management

Darian Sundar – Audio design

Steve O’Brien – Programming

Mike Snooks – Site manager/technician

Mike Willis – System drawings/logistics

Adam Dudding – Installation technician

Lucas Rusden – Installation technician

MORE INFORMATION

Liquid Automation: www.liquidautomation.co.nz

Alloy Yachts Vertigo: www.alloyyachts.co.nz/yachts/sailing+yachts/Vertigo.html

RESPONSES