Silver Lining

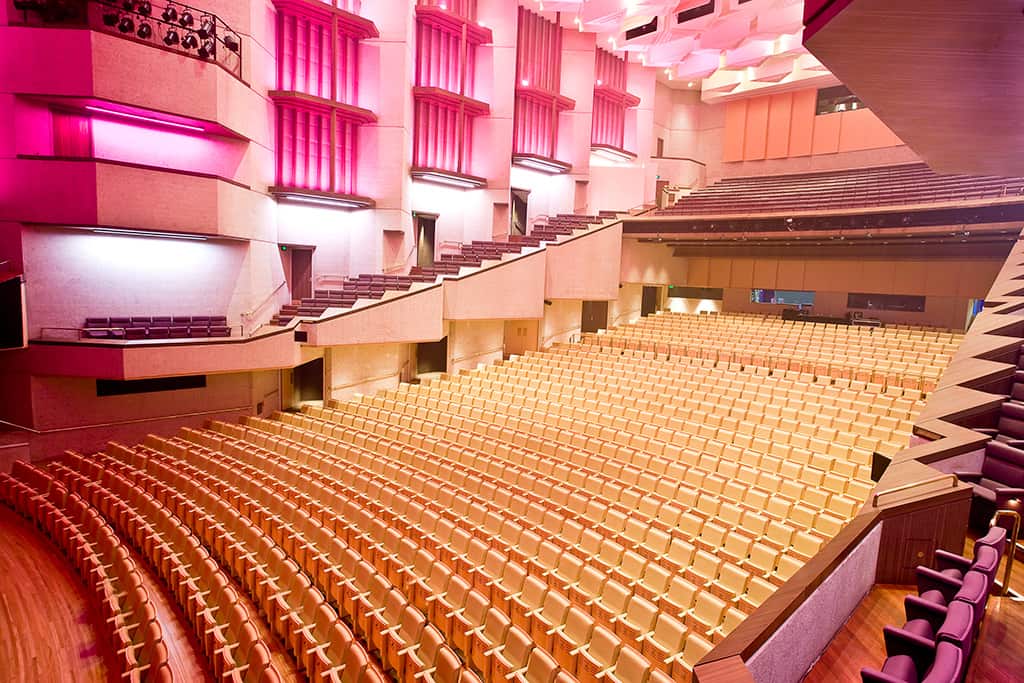

QPAC celebrates its 25th anniversary with a $35m refurb.

Text:/ Stephen Bruel

This year the Queensland Performing Arts Centre (QPAC) celebrates 25 years of world-class theatre, music, dance, and family entertainment. Opened in 1985, QPAC was designed to be Queensland’s cultural hub. Original architect Robin Gibson designed the centre to be “…a true home which will not only satisfy the demands of the performing arts, but will also demand the contribution of artistic excellence by the performer, the performance and the audience.”

As a ‘second home’ to the Queensland Theatre Company, Queensland Ballet, Queensland Symphony Orchestra and Opera Queensland, QPAC comprises the 2000-seat Lyric Theatre, the 1800-seat Concert Hall, the 850-seat Playhouse, the 312-seat Cremorne Theatre, and other areas for food and beverage, reception and conferences.

COLD SHOULDER TO WARM HAND

Changes in the way the building is used, coupled with technological advancements, energy efficiency improvements, and a need to provide greater access for the public within and around QPAC, led to a $34.7m refurbishment project funded by the Queensland Government in 2009. The refurbishments included acoustic enhancements, audio, visual and lighting upgrades, staging improvements and greater access and seating choice for patrons with mobility issues.

“Before the refurbishment, QPAC could be seen as a kind of walled fortress,” said QPAC CEO John Kotzas. “We could have performances in all venues, the whole place packed, and nobody walking past the place would be aware of what was going on. We now have better defined entrances and a more open feel.”

ACOUSTICS ON WHEELS

Marshall Day Acoustics was brought in to ensure the acoustic quality of the project. Acoustics engineer Peter Holmes was respectful of the original acoustic design and aware of what enhancements needed to be undertaken. “Gibson [the original architect] did a great job so we knew we had an excellent shell to work with,” Holmes said. “However, although originally built acoustically for a symphony orchestra, these days the Concert Hall is a multi-purpose space and needs to be flexible enough to accommodate an amplified performance. We also had to consider the sonic qualities for patrons with mobility issues.”

To improve the acoustic flexibility of the Concert Hall, Holmes specified rear absorptive curtains to assist the existing sidewall absorption panels, all designed, manufactured, and installed by Jands. On rollers, the banners can be either controlled individually or deployed to preset positions to suit the acoustic requirements of a particular show at the press of a button. The material used was a tan coloured wool with a faux woodgrain sewn into it to complement the aesthetics of the room – 500km of cosmetic thread in total. The top rear curtain also features a cut-out to allow for stage visibility from the control box.

“There are two large rear-wall acoustic banners and 14 side wall units that can now be individually deployed to alter the acoustic characteristics of the room,” said Jands Project Manager, Peter Grisard. “The primary challenge here was the fact that the rear banners were 16 metres long and curved.”

INTELLIGIBILITY TWEAKS

Holmes also saw problems with the construction of the stage shell and decided to curve the walls and shorten the length between them, resulting in moving the sound more efficiently out into the audience and providing better clarity for the orchestra. He also made adjustments to a curved concrete rear wall that had previously focused sound from the rear, creating a timing delay for the performers, and generally reducing the intelligibility of sound in the room.

“A lot of acoustics is based on what the audience hears, whereas the focus should also be on the musicians,” said Holmes. “If the musicians cannot clearly hear themselves or other members in the group, this can hinder their performance.”

The original seating was replaced to improve both the wheelchair access areas and acoustics in the Concert Hall and Lyric Theatre. CEO Kotzas explained that a new aisle option now allows seating to be pulled out to accommodate wheelchairs, and place these patrons in an acoustically and visually desirable part of the performance space.

REVERB FULL V REVERB EMPTY

The acoustic improvements in the new seating entail absorption slots built into base of the seat cushion. As the seats tip up and face the stage when nobody is sitting in them, the sound absorption in the room remains similar, whether or not the seat is occupied.

“The acoustics of a room change dramatically when it is occupied as opposed to unoccupied,” Holmes said. “You want to try and minimise the difference so that when an orchestra rehearses in an empty room, the difference in sound is not a huge leap to that attained with a full room.”

As the Lyric Theatre ranges in performance from opera through to spoken-word theatre, Holmes had to create a space with less reverberation so a more direct ‘vocal’ sound could be produced. To achieve this, Holmes laid carpet on the floor and installed acoustically absorbent panels and banners in addition to the special seating.

SOUND CHOICES

The scope of the redevelopment works included improvements to the hearing impaired systems, but John Kelly, QPAC Manager Audio/Visual Services, had reservations on the recommendations.

“I resisted input from consultants to change two of the existing Sennheiser infra-red assisted listening systems to radio-based ones,” said Kelly. “Radio-based systems introduce frequency management, multi-pathing, and intermodulation issues. It’s also important to maintain consistency across all of our venues because it affords us the opportunity to share resources between venues. Also the Sennheiser stethoset style listening devices use removable rubber ear-pieces, which we can sterilise between uses.”

The Lyric Theatre’s setup consists of a Midas XL200 40-channel console, Meyer CQ1 and CQ2 speakers for the left and right PA, Meyer UPA1P for the centre cluster, Meyer UPM1P and 2P as the delay speakers, Klark Technik DN360 EQs, dbx compressors, Lexicon effects units, and BSS Soundweb networked signal processors.

The Concert Hall audio setup is similar except for Meyer MSL4 speakers for the PA, Meyer UPM1P nearfield monitoring for the choir stalls, Dolby Lake processors, and a Midas Heritage 2000 48-channel console. A Studer Vista 5 SR digital live console is also available. The microphone list includes Neumann U87, TLM170 and KM184, Schoeps, AKGs, Schertler piano pair, DPA headsets and Shure Beta 87, SM57, SM58, and the Shure UHF-R wireless system featuring the wireless workbench software.

LIGHT THE WAY

The refurbishment included major improvements to the energy efficiency of the building’s architectural lighting, culminating in winning the Illuminating Engineering Society (IES) Award of Excellence.

“In the Concert Hall we replaced the 300W PAR56 houselights with LED fixtures, and replaced the 2.5kW Selecon Arena profile spots with the more efficient 80V (1.2kW) Selecon Pacific luminaires, resulting in an overall 62% reduction in power consumption,” said QPAC Lighting Manager, Doug Brimblecombe. “Additional changes to backstage lighting and general building lighting, reduced power consumption in these areas by 85%.”

A total of 74 Pacific 80V Zoomspots (7.5º–19º and 14º–35º models) have now replaced their older (and much larger) Arena forebears, adding to the 24 x 80V Pacific Zoomspots that had previously been purchased. Those original Pacifics are still being driven from standard phase-control dimmers, but the 74 new units were supplied with DMX-controlled power supplies and are being powered from standard moving light-style power distribution panels. The new FOH configuration includes the first 42 of Morpheous Lights’ PacificFader5 dichroic CMY colour changers, complete with optional dowsers and colour temperature correction. Having so many fixtures with an effectively unlimited colour choice has simplified rigging and focusing, leading to considerable additional cost and time savings.

RETURN OF GRANDMA

MA Lighting’s new grandMA2 (GMA2) platform was selected as the new lighting control system for the Concert Hall, with QPAC purchasing a Fullsize for operation and a Light to back it up [see Paul Collison’s review of the GMA2 on page 48 – Ed]. While originally being run in grandMA1 mode, the consoles are now running with the stable release versions of the native grandMA2 system.

“We sometimes use the GMA2 in the Lyric Theatre or Playhouse as you can now import ASCII console data from older Strand 500 and similar consoles without any issue,” said Brimblecombe. “This includes all the chases and group selects as well as the multi-patch facility it didn’t have before. Now you can assign 20 dimmers to one channel. Whereas the corporate and rock ‘n’ roll world use the groups within the MA, theatre lighting designers want a channel rather than a group.”

STARTING WITH GENESIS

As part of the staging upgrade, QPAC Manager Staging, Tony Maher specified an ASM Genesis hoist control system driving 68 x ASM 400kg steel band hoists in the Concert Hall – again supplied and installed by Jands. According to Grisard, band hoists were chosen as they allow operators to use multiple single-point hoists in a synchronous network as opposed to multi-wire traditional hoisting systems, providing greater flexibility. A further 12 x one-tonne ASM chain hoists were installed for flying speaker cabinets.

“The ASM band hoist solution is unique and offers quiet and fast moving, accurate performance without the capital cost of the infrastructure associated with drum hoists,” said Grisard. “There is also no need for a dedicated winch room.”

New retractable seating (seven rows of 26 seats which occupied 7.3m of stage depth when fully extended) was also installed. All the seats are spring loaded to collapse automatically when retracted, a setup which allows one person to erect half a row at a time, then to stow all seats in a single automated operation.

“The new system enables technicians to do the same work from the stage with just the push of a button, providing a safer, easier, and more efficient work environment,” said Maher.

SMART STAGE

In the Lyric Theatre, Adelaide company Showtrek designed and installed a brand new fully modular flexible stage floor system comprising 60 removable traps, each 3m x 1m, over the main stage area. This system is based on the one devised by Craig Gamble, and built by Showtrek for the Melbourne Theatre Company’s new Summner theatre. These traps have 7.5kPa distributed load and a 20kN point load, and if a stage penetration is required, it is now a quick process to remove whichever sections are required [more details in ‘Theatre of Dreams’, Issue 5 – Ed]. A sprung floor is available when ballet companies perform on stage. Jands supplied 8 x one-tonne and 2 x two-tonne ASM chain hoists for sound rigs in the Lyric.

“The newly increased floor load capacity allows a greater range of elevated work platforms and forklift access to the stage, which in turn assists the technicians in setups and reduces health and safety risks,” said Maher.

RAISING THE BAR

The lighting bars in the Lyric Theatre were also replaced to cater for the ever-increasing demands of theatrical productions. Specialised Stage Engineering (SSE) supplied seven 19m Protrac lighting battens from Prolyte of the Netherlands. The all-aluminium battens consist of a 60mm x 110mm slotted box extrusion connected to a lower 48.3mm-diameter extrusion fitted with an integral Helm runner track to allow the batten to also carry scenery or drapes. Each lighting batten is fed with 36 x 20A lighting circuits via 6 x six-way multicores terminated with standard Socapex connectors.

“SSE and the QPAC team collaborated to design a custom, modular cable tray system that straddles the upper profile of the Protrac bar,” said Brimblecombe. “The downstage side of the tray handles the Socapex looms feeding the bar, while the upstage side has two trays to separate data from power cables. Each tray fixes between the circuit outlets and is attached to the upper profile with a captive nut and bolt, allowing them to be removed if needed.”

QPAC’s extensive silver anniversary refurbishment has not only improved the operational capabilities of its venues and their accessibility to the public, it has also set the centre up for leaner running in a less energy-abundant future over the next quarter century.

CONTACTS

QPAC: www.qpac.com.au

Marshall Day: (03) 9416 1855 or www.marshallday.com

Jands: (02) 9582 0909 or www.jands.com.au

Showtrek: (08) 8382 9398 or www.showtrek.com

SSE: 1300 793 712 or stageengineering.com

RESPONSES